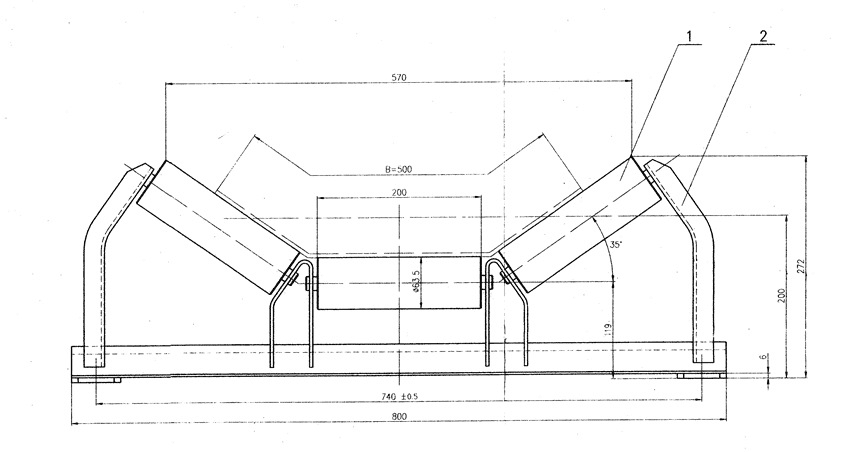

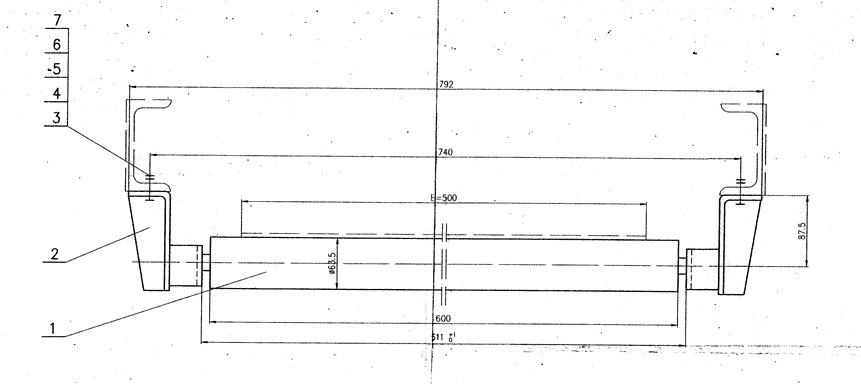

Buffer idler (impact idler), buffer idler is used to slow the impact of blanking on the conveyor belt at the place where the belt conveyor is received. It is mainly developed for the corrosive environment such as coal washing plant, coking plant and chemical plant. Its toughness is more than 10 times that of ordinary metal, its life is five times that of traditional column shoes, and it is corrosion resistant, flame retardant, anti-static. Light weight and other characteristics, widely used in mining. Roller body special polymer material, its mechanical properties are similar to bronze, has good wear resistance, and has good self-lubrication performance, does not hurt the belt. The buffer roller has excellent anti-corrosion performance. Roller body and sealing parts are made of polymer material, corrosion resistance. When used in corrosive situations, the service life can reach more than 5 times that of ordinary rollers.

Performance and advantages

The buffer roller has light weight and small rotational inertia. Roller special polymer material is light in weight, the specific gravity is 1/7 of steel, the roller made of this material, the weight is about half of the ordinary roller, the rotation inertia is small, the friction between the roller and the belt is small.

Use choice of buffer roller for belt conveyor

The application of rollers in belt conveyor is very important, it supports the conveyor belt, and bears the weight of the material. It can be seen that the role of rollers is very important. Therefore, the structural performance of the roller is more important.

Buffer roller special polymer material, light weight, the specific gravity is 1/7 of steel, the roller made of this material, the weight is about half of the ordinary roller accessories, rotation inertia is small, the friction between the roller and the belt is small, effectively reduce the friction between. Reducing the distance between the idlers can reduce the simulated friction coefficient, but the total resistance will increase. The density of the idlers should not be increased in the general bearing section except at the unloading point to protect the tape. In addition, the rubber ring of the buffer roller is resistant to wear and has a long service life. Roller body special polymer material, its continuous performance is similar to bronze, has good wear resistance, and has good self-lubrication performance, does not hurt the belt. There are also many types of buffer rollers, such as spring plate type, buffer ring type, strong buffer type, and so on. So be sure to choose the right choice when choosing. When selecting rollers, it is necessary to pay attention to the radial runout of rollers, the flexibility of rollers, and the axial momentum. In the place where the material drop is greater than six meters, we should choose a buffer roller, which can not only effectively reduce the impact and wear of the belt material, but also prevent the belt from being torn by hard objects.

It can be seen that rollers are very important for belt conveyors. Choosing a good roller can ensure the normal production and improve the efficiency

The conveyor carries the rollers

Conveyor return rollers

Instructions for use

1. The appearance of the roller should be carefully checked for serious bump and damage before use, and the rotating roller should be flexible without jamming.

2. The installation distance of the roller should be determined by scientific calculation depending on the type of logistics and the characteristics of the conveyor, so as to avoid too sparse or too dense installation.

3. Roller installation should be adapted to avoid friction between each other.

Maintenance

1. The normal service life of rollers is more than 20000h, generally do not need maintenance. However, according to the size of the use site and load, the corresponding maintenance date should be formulated.

Timely cleaning oil injection maintenance, timely cleaning floating coal, etc. Rollers with abnormal sound and do not turn should be replaced in time.

2. When replacing the bearing, the opening of the bearing cage must be outward. After the bearing is loaded into the roller, proper clearance should be maintained, and it should not be crushed.

3. Labyrinth seals should be made of original parts, which should be installed in rollers respectively when assembling, and should not be assembled together.

4. When using the roller, avoid heavy objects from hitting the roller tube body.

5. In order to ensure the sealing performance and service performance of the roller, it is forbidden to disassemble the roller at will

Application/field of application

Mine roller:

Ordinary roller: grain, loading and transferring

Trough rollers: coal, cement, electricity

Trough type aligning idlers: Metallurgy. Mining, power, cement, chemical, building materials, steel mills, transportation equipment.

Drum roller: metallurgy, chemical industry, coal, building materials

Ground roller: Applicable field mining

Stop roller, vertical roller: applicable scope conveyor

Hanging roller: Applicable to belt conveyor

Backstop roller: Applicable field metallurgy. Mining, electricity, cement, chemical industry, building materials, steel

Spiral rollers:

1) Screw roller: Applicable scope Coal, electric power, metallurgy, chemical industry, building materials,

2) Spiral cleaning roller: applicable scope of coal mine machinery

3) Two-way spiral rubber roller: suitable for conveyor, packaging machinery, food machinery, mining equipment, other

Parallel rollers:

1) Parallel upper roller: parallel lower roller: Scope of application port transport terminal, mine transport, mechanical equipment

2) Parallel upward core roller. Parallel down core roller: Applicable scope to prevent belt deviation

Comb roller: mine, wharf, coal, power plant, coking, export trade

Conical roller:

1) Cone upward core roller: Applicable fields port, power, coal mine, machinery factory, grain transportation, chemical industry

2) Cone down core roller: Applicable fields port, electric power, coal mine, machinery factory, grain transportation, chemical industry

Friction roller: metallurgy, chemical industry, coal, building materials

1 Friction lifting core roller. Friction reducing core roller: applicable scope conveying machinery

Buffer roller: Applicable to power plant, cement plant

Rubber ring buffer roller: Applicable scope roller special

Parallel buffer roller: applicable to coal mine

Adjustable groove Angle double spring buffer roller group: applicable scope port transport wharf, mine transport, mechanical equipment

Spring plate buffer roller: applicable range conveyor

Three articulated rollers: Coal mine, wharf, export trade, conveyor.

Copyright @ Huizhongxing All Rights Reserved 2024

Good

Admin on March 21, 2024The product is very good and has a beautiful appearance. We will cooperate more in the future.

Good

Admin on March 16, 2024The product quality is very good.

Good

Admin on March 09, 2024Fast construction period and excellent quality.

Good

Admin on March 09, 2024The after-sales service is excellent, and we can actively communicate and solve any problems!

Good

Admin on March 09, 2024I will repurchase in the future if needed!